Your Cart

Precision Meets the Trail:

Why BITEHARDER Was Born

Glenn Welch had been building precision aerospace and defense parts for decades.

As the owner of Welch Manufacturing, he spent his days machining some of the world’s toughest materials with carbide tooling. But his true escape was snowmobiling the backcountry trails of New England and Quebec.

One winter ride through the Quebec backcountry changed everything. Glenn entered a corner like he’d done a thousand times, but this time his sled didn’t hold the line. He went headfirst into a ditch, totaling the machine. When he got home and inspected the damage, he saw the cause: dull carbide runners.

Glenn had the rare combination of experience and perspective to see what others hadn’t.

With decades of carbide-cutting expertise, he realized this problem could easily be avoided. There was no reason snowmobilers couldn’t sharpen their runners the same way his machines had done in the aerospace world—using diamond-coated technology.

That crash didn’t just wreck a sled—it sparked an idea. The result was the first BITEHARDER product: a diamond-coated carbide runner sharpener that could be used right on the sled with a cordless drill. No downtime, no hassle—just sharper handling and restored control in minutes.

Since that first product, BITEHARDER has continued to grow—adding products designed to make snowmobiling safer, more efficient, and save you money.

From runner and stud sharpeners to helmet lights, PolyTune rings, and pro-grade support tools – everything we build creates simple fixes for problems riders have tolerated for years.

Sharpen runners & studs instead of replacing them.

Align your track without hours of trial and error.

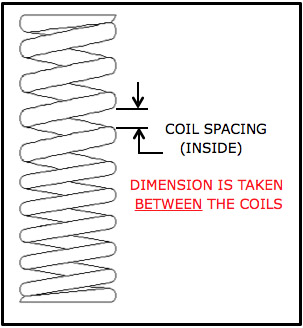

Tune your front suspension springs to reduce chatter & fatigue.

Hold your sled on it's side for maintenance without risking injury.

Stay visible when snow dust, fog, or darkness hits.

Stay stylish and warm with BITEHARDER swag.