Your Cart

FAQs

Sharpening Tools

Like any cutting tool (drill, grinding wheel, etc.), the life expectancy of our carbide runner and stud sharpening tools is a factor of how you use the tool. To get the most life from our tools follow all instructions that came with your tool or can be found by clicking HERE. Some guidelines are listed below;

Our Standard Series Carbide Runner Sharpening Tool is an edge maintenance tool designed to run at slower RPM’s using a cordless drill on its fastest setting. We suggest you start with a new set of carbide runners, or a pair that has less than 500 miles on them, and maintain the edge with the sharpening tool every 200-300 miles. The more you sharpen your runners, the less material that needs to be removed, and the longer the tool will last.

Our Professional Series Carbide Runner Sharpening Tool has a much higher grade diamond cutting media and bonding material, and is designed to run at higher speeds (10,000 RPM/s plus in an electric or pneumatic grinder). With proper use this tool will last 5 times longer than our standard series tool and will sharpen even a significantly worn set of carbide runners.

Our Standard Series Carbide Stud Sharpening Tool is designed to touch up individual studs that are significantly work or broken. It also is designed to run at slower RPM’s in a cordless drill (on its fastest setting) to provide convenient any time sharpening.

Our Standard Series Carbide Stud Sharpening Tool is designed to touch up individual studs that are significantly work or broken. It also is designed to run at slower RPM’s in a cordless drill (on its fastest setting) to provide convenient any time sharpening.

Our BITEHARDER® Carbide Runner Sharpening Tools work with all manufacturers style of carbide runners, regardless of the stock angle that comes from the manufacturer (60 or 90 degree).

The geometry of the tool allows you to put an “extended edge” on the carbide runner that we call our AdvantEdge™. This allows you to maintain a consistent edge over more miles of riding.

With our patented BITEHARDER® AdvantEdge™ your carbides will stay sharp up to 250 miles depending on riding conditions. Testing has shown that our AdvantEdge™ technology even outperforms the factory edge you receive from a new set of carbide runners.

NONE! However the performance and safety benefits you get by riding on sharp carbide runners every time you head out on the trail is invaluable. Thousands of miles of testing has shown that carbide runners that are kept sharp, do not wear any faster than carbide runners that are not sharpened. Experience has shown that sharp carbide runners reduce darting, let you corner more confidently, and help you to avoid hitting trees.

Carbide studs are manufactured with a stud core that extends about ½ and inch into the stud body. This allows you to sharpen your studs 4 to 5 times before needing to replace them, resulting in a cost as low as $0.31 per stud. At a cost of $3.00 to $5.00 per stud to replace, the savings are significant. Additionally, BITEHARDER Stud Sharpening Tools put a 60 degree edge on your stud providing a better tip than what comes new from the manufacturer. At BITEHARDER we say, “Hook Up and Hold On”.

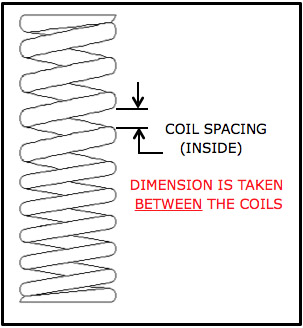

PolyTune® Suspension Rings are designed to take your snowmobiles linear rate spring, and make it a more progressive or dual rate spring (see diagram). Snowmobile manufacturers do not use progressive rate springs because of their cost and complexity. Progressive rate springs provide faster reaction times to inputs with your front suspension. This results in flatter cornering, better bump compliance, and less rider fatigue at the end of the day.

Yes you can but these types of springs can run between $600.00 to $1500.00 per pair. BITEHARDER’s PolyTune® Rings give you 90% of what a replacement progressive shock provides, at a fraction of the price. In addition, you can use our different densities (soft, medium and hard), to tune your springs to your exact riding style.

BITEHARDER® manufactures precision diamond coated sharpening tools to the highest quality standards, but like any cutting tool they will wear out over time. It is for this reason we can only process a return on products that have not been opened and were purchased within the last 30 days. However our goal is 100% customer satisfaction. Please contact us with any issues or concerns you may have. We will gladly look at these on a case by case basis.

Help them out once, but then tell them to go to www.biteharder.com to order their own tool. Our manufacturing facility is set up to ship the same day your order is placed.